Potable Water

Coating or Lining systems for steel and concrete potable water tanks are unique as they need to meet the NSF/ANSI 61 standard, as well as have good performance properties. EonCoat chemically bonds to steel and concrete tanks, with flex and elongation characteristics that adapt to the stresses endured by water tanks. Changes in air temperature, sun heating and wind deflection can cause expansion, contraction and movement of a tank's structure. Older coating technologies may disbond and fail when undergoing environmental stresses, but EonCoat’s chemical bond and flexibility enable it to withstand these dynamic changes.

Installation of EonCoat is a spray-up application, with no VOCs or HAPs emitted in the process. The cure time is just a matter of minutes, allowing for a one coat, high build, quick application and return to service with minimal downtime. EonCoat is safer to use in confined spaces than other coatings because it has no VOC's and cannot ignite. It virtually eliminates the risk of a flashpoint fire and the risk of a worker succumbing to fumes.

Water/Wastewater

Waste Water Treatment Plants are subject to harsh chemicals, liquids and gases that will erode the wastewater tanks and containments if not properly coated. During the water treatment process microbes generate Hydrogen Sulfide (H2S) as a byproduct. H2S has a low solubility in wastewater and as it escapes from the wastewater moving into the air the rotten-egg odor is easily recognized. The acidic nature of H2S is responsible for severe corrosion problems and toxic conditions within wastewater conveyance and treatment facilities.

Waste Water Treatment Plants are subject to harsh chemicals, liquids and gases that will erode the wastewater tanks and containments if not properly coated. During the water treatment process microbes generate Hydrogen Sulfide (H2S) as a byproduct. H2S has a low solubility in wastewater and as it escapes from the wastewater moving into the air the rotten-egg odor is easily recognized. The acidic nature of H2S is responsible for severe corrosion problems and toxic conditions within wastewater conveyance and treatment facilities.

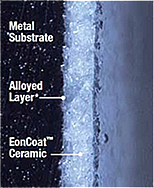

The patented new technology of EonCoat chemically bonds to concrete and steel creating a new passivation layer which is non corrosive protecting the substrate. This new protective alloy is then covered with a flexible, protective ceramic. EonCoat puts a chemically bonded barrier separating the structural wall from the harsh environment of the water stream. EonCoat provides two layers of protection in one coat. EonCoat is a fundamentally different coating technology. It is based on a revolutionary “self-fired ceramic technology” developed by the U.S. Department of Energy and Argonne National Laboratory to encapsulate nuclear waste.

Facilities can save thousand of dollars using EonCoat, in capital replacement costs and recoating costs due to the traditional peeling and flaking issues of traditional coatings and linings. EonCoat’s corrosion protection stops rust and erosion of substrates even in such harsh conditions found in Waste Water Treatment Plants. EonCoat bonds to metal or concrete substrates, converting surfaces to bonded ceramics. This newly formed ceramic surface is hard, nearly insoluble, and impervious to oxygen and moisture.

Facilities can save thousand of dollars using EonCoat, in capital replacement costs and recoating costs due to the traditional peeling and flaking issues of traditional coatings and linings. EonCoat’s corrosion protection stops rust and erosion of substrates even in such harsh conditions found in Waste Water Treatment Plants. EonCoat bonds to metal or concrete substrates, converting surfaces to bonded ceramics. This newly formed ceramic surface is hard, nearly insoluble, and impervious to oxygen and moisture.

Water Tanks for Fire Suppression

The corrosion resistant, fire-retardant, abrasion resistant properties of EonCoat make it ideal for use for Fire Suppression tanks. Many commercial and industrial buildings have water storage vessels to supply or supplement their fire sprinkler systems and may also be used as a back up for potable water. These tanks, usually steel, concrete or fiberglass, may often be located on the roof or on a floor near the top of the structure to allow gravity to help supply delivery pressures. Over time these tanks may develop problems to exterior or interior coatings. Due to location, replacing these tanks is a major capital expense, and highly disruptive to a facility's operation. Since fire suppression systems are of major concern in a building's insurance coverage, the insurance company can take into consideration the condition of these vessels into underwriting and renewal, causing building manager’s to look for economical solutions for rehabilitating the tanks.

EonCoat works well in traditionally restricted places fire suppression tanks are found. The NSF/ANSI 61 standard compliance also makes Eoncoat ideal for tanks that are used for both fire suppression and potable water storage.

Short Downtime

Reduced Liability